Whether you’re looking for a pair of curved jaw locking pliers, or straight jaw pliers, or if you’re in need of a good pair of needle-nose locking pliers, locking pliers with a built-in wire cutter, or a 3-piece locking pliers set for heavy-duty professional or home use, you’ll find what you need on our below list of the best pliers available to buy now. Thomas’ Top Picks for the Best Locking Jaw Pliers 2023 Here is a list of the best locking plier grips, followed by a buying guide to help you select the best locking plier grip for your needs. A pair of good quality locking pliers is a must in every tool box Also known as a mole grip or a vise grip (the first-ever trademarked Vise-Grips tools were invented in 1924 in Nebraska), these tools’ serrated jaws can clamp down on an object and grip it securely with pressure, thus staying in place for you to perform any necessary task, such as holding metal materials together during welding, hands-free. You’d be hard-pressed to find a much-used toolbox without a good pair of locking pliers inside. When you purchase products through our independent recommendations, we may earn an affiliate commission. Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. Get yourself a piece of a best industrial bench vise and you could rest on your laurels without compromising on the quality.Įditor's note: This article represents the independent views of the author and should not be construed as a National Safety Council endorsement.Welcome to the Thomas guide to the best locking plier grips 2023. Simply because quality never compromises and welds as in the case of cheaper and non-functioning pieces. In a nutshell, if there are any specific words that work better in the handling of bench vise is the use of quality hand tools vices. Never attempt to weld the vise by self-repairing.Replace the part or the vise immediately if you notice stress fractures.Hand pressure on a vise is designed to hold until limited lining.

Don’t proceed to tighten the vise more than is required.Stay away from the handle extension and extra clamping pressure to ensure you don’t damage your work surface and vise.Never attempt to widen the jaws of the vise more than they have been designed for.

#Vice tool has teeth full#

Check the clamping of the vise on the surface to see whether it offers full clamping.Keep the vise and material size at a substantially compatible range.In fact, always have a glance over the work surface and see for yourself whether the table or the surface holds firm under duress. Keep the stationary jaw at a length of slightly beyond the working table to keep the long pieces away from interfering.Always ensure the bench vise is securely fitted to the work table, with bolts placed in the right order.Cover your face and eyes with a shield, goggles and safety glasses.Here’s what you need to do to stay safe while using a bench vise: The device is widely used in the mechanical and woodworking industries, among others.

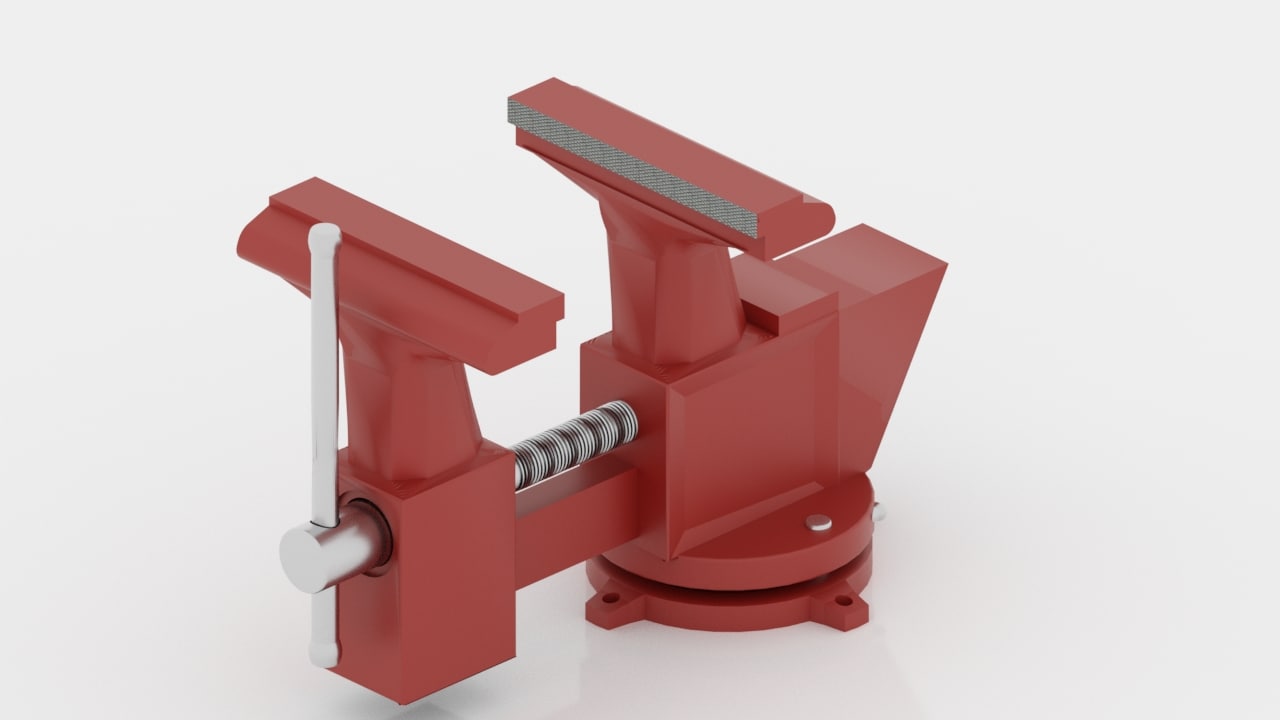

It features two parallel jaws as part of the design. To state in simple terms, a bench vise is a mechanical apparatus used to secure an object that is to be worked on. But users need to first understand some safety tips and warnings. A bench vise has proven to be quite a substantial piece of armor when it comes to performing work tasks. Responding is Andy Kelson, marketing manager, JCBL Handtools, Chandigarh, India.Īnswer: Safety precautions are necessary when it comes to the handling of mechanical instruments and panels to ensure incidents and injuries do not occur.

0 kommentar(er)

0 kommentar(er)